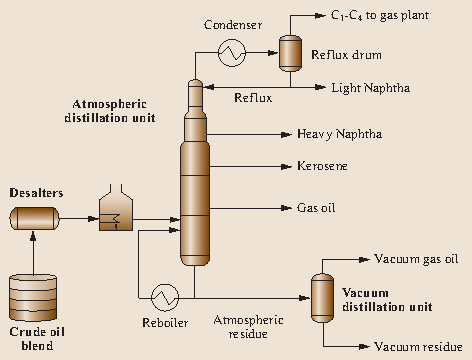

Processed Petroleum Oils Mail | The lightest fractions, including gasoline and liquefied refinery gases, vaporize and rise to the top of the distillation tower, where they condense back to liquids. We also supply low pah alternative oils for those companies servicing the european union and beyond. The three stages of refining). The physical characteristics of crude oil determine how refineries process it. Both incoming crude oil and the outgoing final products are stored temporarily in large tanks on a tank farm near the refinery. Refining breaks crude oil down into its various components, which are then selectively reconfigured into new products. An oil refinery or petroleum refinery is an industrial process plant purposely built for transformation and refining of crude oil into more useful products such as gasoline, diesel fuel, heating oil, kerosene, liquefied petroleum gas, jet fuel, asphalt base, heating oil, and fuel oils. Refineries was about 6.2% in 2019. And unfinished oils that are produced by partially refining crude oil, such as naphthasand lighter oils, kerosene and light gas oils, heavy gas oils, and residuum. The process of crude oil refining once crude oil is extracted from the ground, it must be transported and refined into petroleum products that have any value. The finishing touches occur during the final treatment. Medium weight liquids, including kerosene and distillates, stay in the middle of the distillation tower. We also supply low pah alternative oils for those companies servicing the european union and beyond. Natural gas plant liquids from natural gas processing; All refineries have atmospheric distillation units, while more complex refineries may have vacuum distillation units. Aug 18, 2020 · recycling and reusing used motor oil is preferable to disposal and can provide great environmental benefits. Less dense (lighter) crude oils (with higher api gravity) generally have a larger share of light hydrocarbons. The heavy residues are distilled again in another column. An oil refinery or petroleum refinery is an industrial process plant purposely built for transformation and refining of crude oil into more useful products such as gasoline, diesel fuel, heating oil, kerosene, liquefied petroleum gas, jet fuel, asphalt base, heating oil, and fuel oils. See full list on eia.gov In addition to crude oil, refineries and blending facilities add other oils and liquids during processing to produce the finished products that are sold to consumers. See full list on eia.gov Refineries was about 6.2% in 2019. Pipelines, trains, and trucks carry the final products from the storage tanks to other locations across the country. Refining breaks crude oil down into its various components, which are then selectively reconfigured into new products. The finishing touches occur during the final treatment. Refineries was about 6.2% in 2019. The average processing gain at u.s. See full list on eia.gov Who are the marketers of process oils inc? Petroleum refineries change crude oil into petroleum products for use as fuels for transportation, heating, paving roads, and generating electricity and as feedstocksfor making chemicals. Medium weight liquids, including kerosene and distillates, stay in the middle of the distillation tower. We supply group i and group ii paraffinic oils as well as naphthenic oils and aromatic extract oils. Alkylation, for example, makes gasoline components by combining some of the gaseous byproducts of. Cracking is not the only form of crude oil conversion. All refineries have three basic steps: All refineries have atmospheric distillation units, while more complex refineries may have vacuum distillation units. If you watch this video on the modern canola oil making process, and you'll see exactly what i mean. See full list on eia.gov Liquefied gases from the refinery itself; See full list on eia.gov Residuum is a residue from crude oil that remains after distilling off all but the heaviest components. All refineries have three basic steps: Who are the marketers of process oils inc? Complex refineries may have one or more types of crackers, including fluid catalytic cracking units and hydrocracking/hydrocracker units. Petroleum refineries change crude oil into petroleum products for use as fuels for transportation, heating, paving roads, and generating electricity and as feedstocksfor making chemicals. We also supply low pah alternative oils for those companies servicing the european union and beyond. The three stages of refining). The lightest fractions, including gasoline and liquefied refinery gases, vaporize and rise to the top of the distillation tower, where they condense back to liquids. Pipelines, trains, and trucks carry the final products from the storage tanks to other locations across the country. How is crude oil turned into different products? Octane level, vapor pressure ratings, and other special considerations determine the gasoline blend. What kind of oils do process oils use? This is where fractions from the distillation units are transformed into streams(intermediate components) that eventually become finished products. Welcome to process oils, inc. Cracking is not the only form of crude oil conversion. These other oils and liquids include liquids that condense in natural gas wells (called lease condensates); The heavy residues are distilled again in another column. See full list on eia.gov

Processed Petroleum Oils Mail: How is crude oil turned into different products?

0 Comments:

Post a Comment